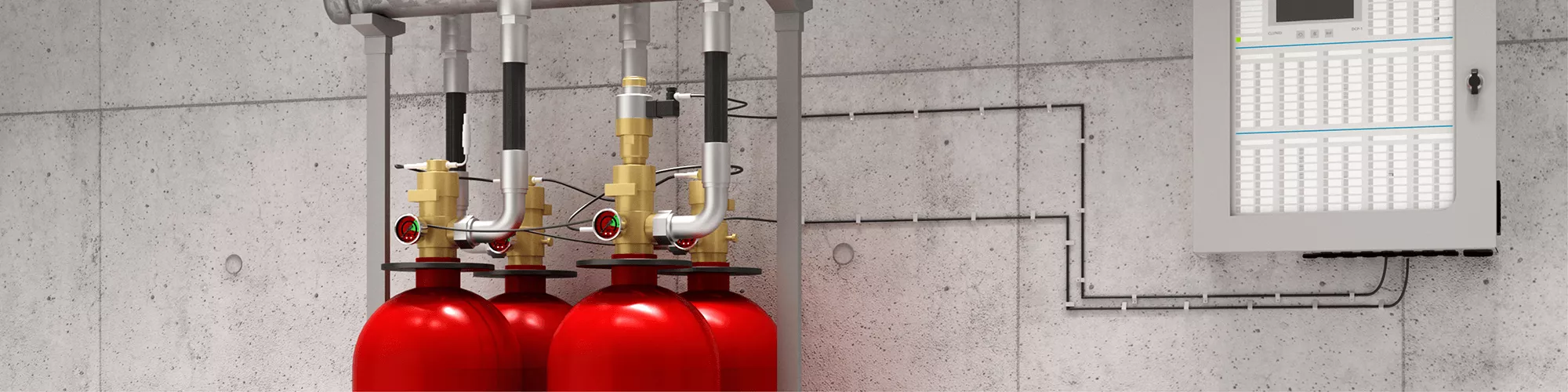

Oxeo – fire fighting with natural gases

Oxeo fire extinguishing systems use pure argon, nitrogen or blends with CO2 to extinguish fires. These natural inert gases are particularly effective as extinguishing agents – especially in high risk fire areas. These systems are especially suitable for the protection or areas containing valuable and sensitive equipment as they are electrically non-conductive and leave no residues.

Oxeo extinguishing systems have a three-dimensional effect in the entire extinguishing zone.

The released inert gases disperse homogeneously in the event of a fire and displace the oxygen at the source of the fire. Even hidden fire sources are, as a rule, extinguished instantaneously, not even spray obstructions present a problem. Oxeo extinguishing systems are therefore perfectly suited to providing fire protection for specific hazard areas with flammable liquids and other hazardous substances, as well as high risk fire areas.

Personal safety

Argon and nitrogen are not toxic in the concentrations required to extinguish fires – however, when released, the oxygen concentration is always significantly lower compared to the ambient atmosphere. For this reason, Oxeo extinguishing systems provide warnings to anyone present in the extinguishing zone through acoustic and optical alarms to evacuate the zone before the extinguishing process starts. These systems can also be used in areas that are accessed by people.

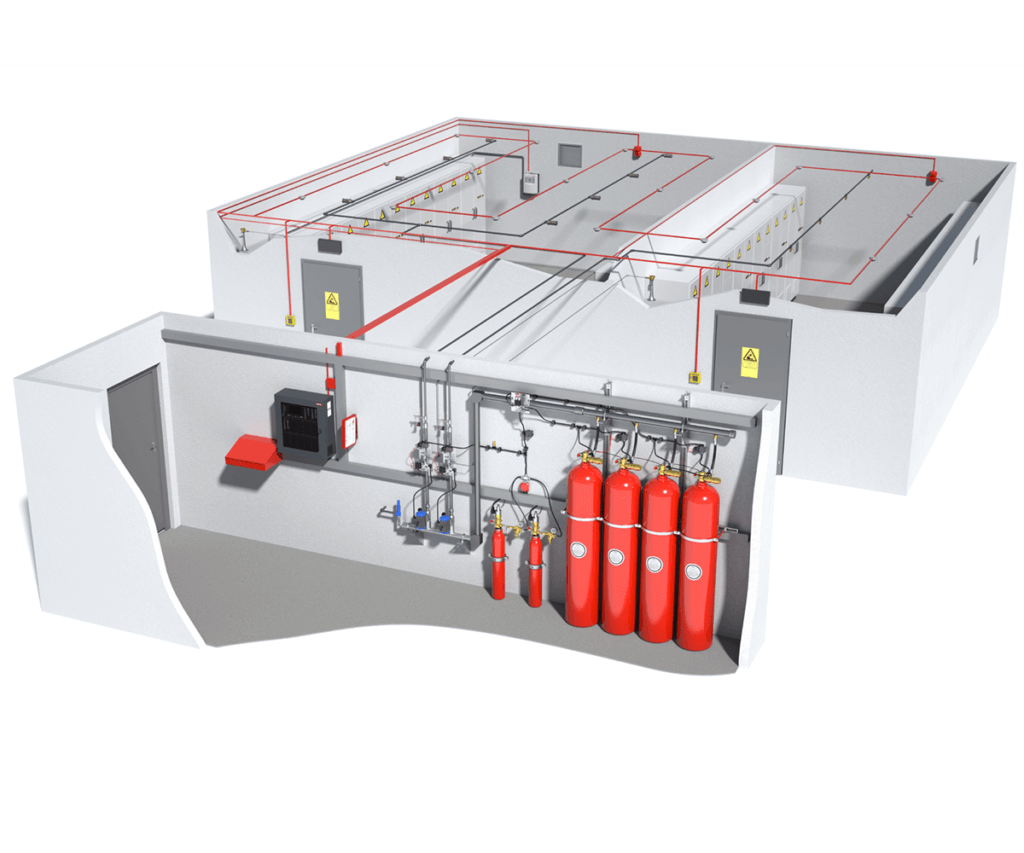

Oxeo LCP system illustration (simplified)

Legend

Cylinder battery, for operation and reserve

Pilot cylinders for operation and reserve.

Clunid DCP-1 panel

Acoustical and optical notification device

Manual call point

Natural inert gases explained

Argon (IG-01)

Argon is a noble gas obtained from the ambient air and present at 0.93% in the natural atmosphere by volume.

Its density compared to air is 1.38 : 1. As argon is considerably heavier than air it is particularly suitable for spaces, such as false floors, that are less well insulated in their upper part. Due to its high degree of inertia (“true” inert gas), argon is also especially suitable for metal fires.

Nitrogen (IG-100)

The natural atmosphere contains 78.1% Nitrogen by volume, with a density of 0.967 : 1 compared to air.

Nitrogen thus has a similar density to air, which permits nitrogen to disperse optimally throughout the extinguishing zone and to maintain an extinguishable inert gas concentration over a particularly long period. This qualifies nitrogen as a universal extinguishing agent for a broad range of applications.

Mixed gases (IG-55 / IG-541)

Mixed gases – containing both argon and nitrogen, and optionally small amounts of carbon dioxide – may also be used in Oxeo extinguishing systems. Typical mixed gases for the use in inert gas extinguishing systems are IG-55, consisting of 50% argon and 50% nitrogen, as well as IG-541, consisting of 52% nitrogen, 40% argon and 8% carbon dioxide.

Storage and supply of extinguishing agent

The extinguishing agent is stored in high-pressure gas cylinders, which are then used in combination, enabling both the optimization of available space and extendibility of the Oxeo storage system. The filling pressure of every single cylinder is constantly monitored for leakage with pressure gauges and the results are displayed.

Any error messages are transmitted to the fire detection and control panel. This means that the quantity of available gas is constantly under control. The required quantity of extinguishing gas to be stocked depends on the fire hazard and the size and nature of the protected facility.

The modular structure of the Oxeo storage system permits perfect adaptation to the customer’s individual needs and local conditions and offers maximum flexibility, especially for system modification or extension.

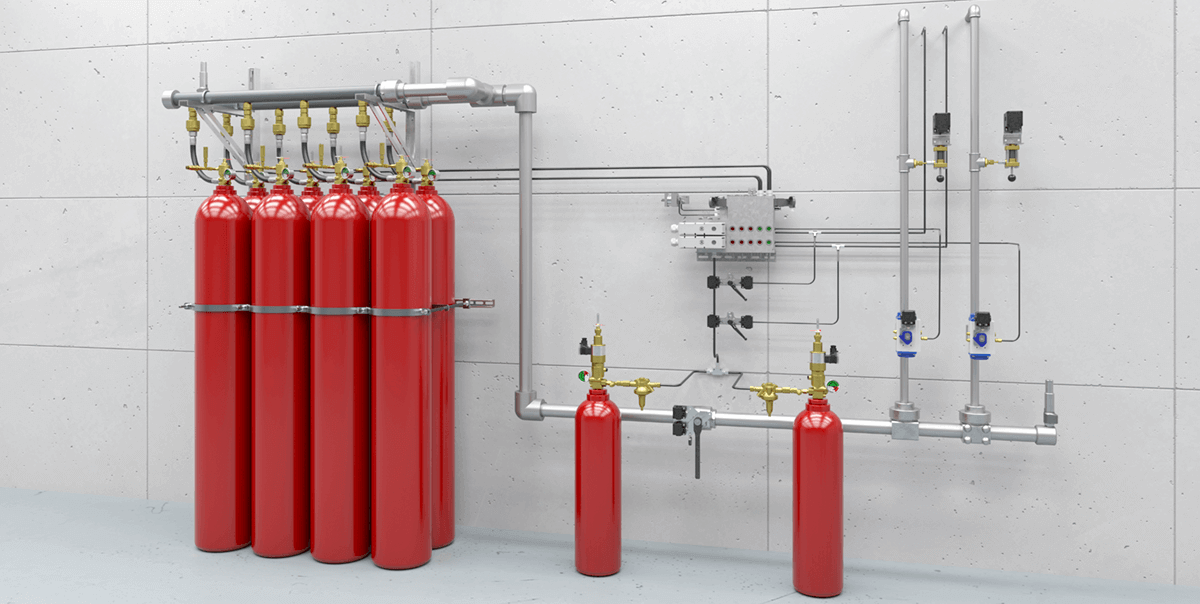

Oxeo inert gas system | Cylinder battery in technical room

Oxeo ConstantFlow Technology

In conventional inert gas extinguishing systems, the gas escapes from the cylinders into the pipe network at the beginning of the extinguishing process with a charging pressure of up to 300 bar. This creates a pressure spike at the beginning of an extinguishing process as well as a heavy stream of extinguishing agent which rapidly decreases with the duration of the flooding.

Oxeo ConstantFlow Technology operates with high-performance pressure regulators mounted directly on the gas cylinder valves. At the start of the extinguishing procedure the operating pressure is thus already reduced to a maximum of 60 bar at the output of the gas cylinders. In addition a constant stream of extinguishing agent is created without a pressure spike.

When using Oxeo ConstantFlow Technology the connected conduits and system components need only to be designed for the low pressure level of 60 bar maximum.

Legend

Applications

Typical areas of application for Oxeo inert gas systems are:

- Control stations, operation and control rooms

- Data center, server rooms and server racks

- Technical rooms

- Painting and powder coating systems

- Storage facilities for hazardous substances and flammable liquids

- Paternoster storage

- Machine tools

- Museums, archives

Museum archive protected by Oxeo Contant Flow Technology

Image source: Minimax-Viking, Michael Kromat | Minimax-Viking, Markus Pfeiffer| Viking S.A.